A first time (golden era) Kswap start-up can be an exciting and aggravating experience all at once. Most of the time its aggravating due to unforeseen BS that prevents a clean start up. It can be a simple thing like a single ground wire to a string of dumb ass things. Below is a semi rough list of common Kswap startup issues I’ve compiled…

Wiring & ECU Based Issues

- Ground wires & general grounding

Kswaps are HELLA sensitive to grounds. If you don’t run the minimal amount you risk having startup issues and just overall weird ass electrical behavior. You MUST run at least 2-3 (or more) ground wires for the swap. 2 off the transmission to the left frame rail is mandatory, engine harness to a valve cover stud (per Hondata’s advice and not on the intake manifold!), optional but off the backside of a valve cover stud to the right side shock tower or off the VTEC solenoid body. Up to you on the aesthetics just get the got damn grounds on there! - Grounding main relay pin#2 (an EK civic issue mostly)

So, this one seems to mostly be an EK civic specific issue from my experience. I’ve seen this happen with Rywire, Hybrid Racing, and Ktuned brand conversion harnesses. It has something to do with the wiring template these makers use. I don’t know who copied who but they all have the same issue where the symptom is the vehicle will not get any power to the ECU nor to the fuel pump. The fix for this is by fishing out the EK’s main relay and then adding a wire to the #2 wire spot on the main relay, and then grounding it directly to the chassis as shown in the photo. Again, aesthetics is up to you. - JDM vs USDM ECU fuel pump relay pin differences

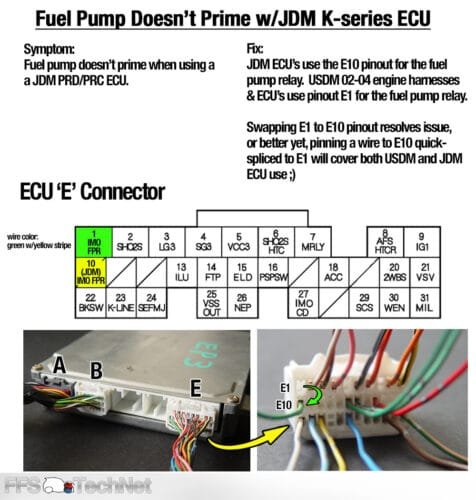

JDM and USDM K-series ECU’s use different pinouts for the fuel pump relay (FPR). This is because of the immobilizer system US ECU’s have and JDM 01-04 ECU’s lack (I believe the 05-06 JDM RSX ecu’s actually have an immobilizer system). ECU connector E1 is for USDM ECU’s FPR and E10 is for JDM ECU’s FPR. So, if you’re using a USDM engine harness (aftermarket or factory) with a JDM K-series ECU your fuel pump isn’t going to activate. The fix is to move pin E1 down to E10 or better yet, find a spare K-series ECU pin w/about 1-2″ of wiring lead and then pin it to E10 and then splice/tap it over to E1, that way you’ll be wired to run a USDM or JDM ECU and never have to worry about the FPR wiring!!

- Aftermarket Chyna tucked engine harness wired wrong from the maker (lookin at you eBay/Amazon shiddy harnesses with big ass stupid yellow labels!)

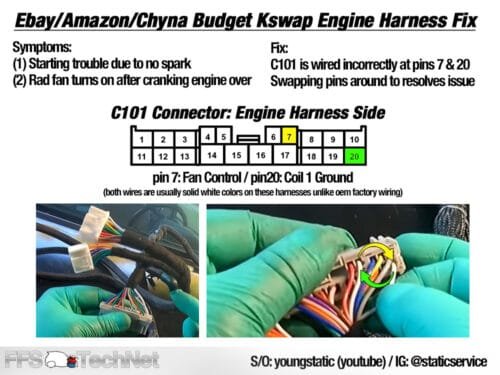

I’m not sure who originally figured this out, but I became aware of this fix through a post within Facebook k20a.org or k-series tech groups that I usually peruse – a link to a Youtuber (YoungStatic) whom shares knowledge regarding these budget ass Kswap tuck harnesses are incorrectly wired at two specific pinouts on the engine harness side of the C101 connector. Pin 7 and pin 20 are crisscrossed. The symptoms experienced during startup attempts are no spark and the radiator fan (if wired up) turns on right after the cranking attempt. The fix is to swap pin 7 and pin 20 around as shown below. PIN 7 is a rad fan switch signal, PIN 20 is for ignition coil pack #1 ground. Stupidly, both of these wires are solid white color instead of matching oem factory wiring colors of solid green for Pin7 and black w/white stripe for Pin20.

- ECU start up map/tune not setup properly

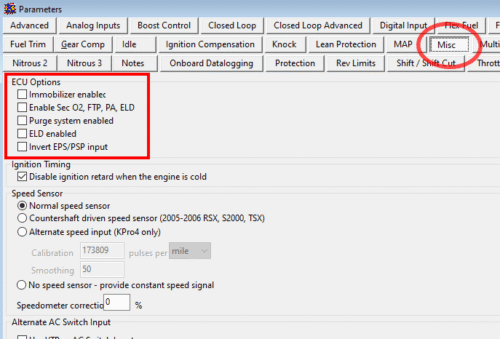

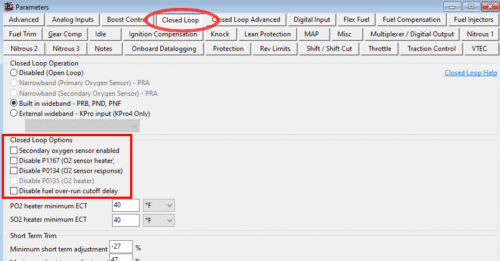

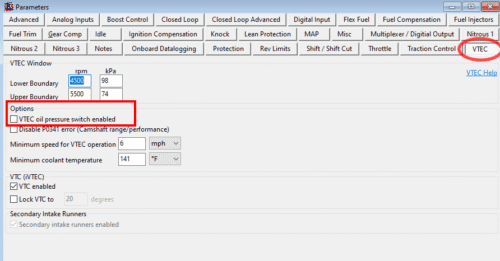

This one is pretty common too. A lot of people don’t know how to setup a startup tune (usually included with the Hondata Kmanager software) as its daunting for them and are scared they might blow up their engine which is understandable. But if they do make the attempt, they either pick the wrong map and continue with changing the wrong parameters. No matter what map is used, these parameters should be disabled:

– Immobilizer system (very important to disable or fuel pump does not work!)

– Multiplexor system

– Second 02 sensor

– Extra OBD2 functions (evap, purge system, ELD-optional)

– VTEC pressure switch (not used on JDM engines)

These are all functions that are useless for a golden era Kswap chassis.

- Disable (uncheck box) Immobilizer & other unneeded OBD2 and emissions functions.

- Disable 2nd 02 and extra 02 functions (optional).

- Disable Multiplexor.

- Disable VTEC pressure switch.

- Crisscrossed ECU connectors (A + E) w/aftermarket wire harnesses

Of the three ECU connectors (A,B,and E) found on aftermarket engine and conversion harnesses, the “A” and “E” connectors CAN BE accidently crossed! Thanks to the manufacturing laziness some of these harness makers have done, they don’t follow the unique factory OEM keyways for A and E connectors in preventing them from being idiot proof and crisscrossed! This is prevalent with tons of aftermarket brand tuck engine harnesses and conversion harnesses especially the trash ass china made budget harnesses you’d find on Amazon/eBay/JackSpania/Bullboost/etc. Symptoms of crossed A & E connectors is startup issues (fuel but no spark) and some other weird behavior. The A and B plugs are usually paired up pretty close to each other and are coming off the engine harness while the E plug is ALWAYS coming off the of the conversion harness – this is a dead giveaway. If they just f*cking labeled the ECU connectors this wouldn’t be a problem! The other fix for this is to double check the wire colors for each pinout but the easier method is already mentioned.

Sensor Based Issues

- MAP & TPS sensors plugs are crisscrossed

This is a VERY common issue among the unknowing because of the same style connector both of these sensors have and are within the same vicinity of each other. This is especially a problem on unlabeled harnesses, like when using a factory OEM engine harness for a swap. When these plugs are crisscrossed in a golden era Kswap vehicle, there’s a 99% chance the MAP sensor will attain damage – internally blows out without any kind of obvious warning- upon vehicle startup (yes its THAT sensitive). I don’t think K-series era vehicles like the EP3 Civic and RSX have this problem. The rub here is that the ECU will NOT throw a CEL light for a bad MAP sensor! Wild right? So, the work around BEFORE VEHICLE STARTUP ATTEMPTS is to double check the MAP and TPS wire colors if you’re using an OEM engine harness for your swap and label them if you’re not sure which connector goes to either sensor. Obviously a kswap tuck harness have labeled sensors, so there’s no problem with those types of harnesses. The symptom of a blown map sensor is a hard startup – spins and hiccups like it wants to start with occasional backfire but will never turn over usually. One way to check (after the damage has been done) is if you’re using a Hondata KPRO ECU with your swap, open up the Hondata Kmanager software on your laptop, put Kmanager into LIVE/Datalog mode (F10 button), open the sensors list and look at the MAP sensor psi reading. If its showing -XXpsi its blown. It should be reading now lower than -XXpsi. - K20 vs K24 crank sensor differences

Everyone knows this by now right?? RIGHT?? K20 and K24 crank sensors differ in pinout wiring and connector key style. If you’re using a typical Kswap engine harness they are usually based of 02-04 RSX wiring, its 99.9% setup to use a K20 crank sensor and not a K24 crank sensor! If you try and use a K24 crank sensor with a Kswap harness pinned to use a K20 crank sensor YOU’RE GOING TO HAVE ISSUES. The only way you’ll get the K24 crank sensor to work is by swapping crank sensor wiring around and modifying the crank sensor connector to accept the K24 crank sensor. Hybrid Racing has a thorough article on this topic. Various symptoms can occur when improperly using a K24 crank sensor (all mentioned in the linked hybrid article). - Camshaft position sensor(s) could be bad (one or both)

The two cam position sensors are located on the left side of the cylinder head. Either of these sensors could be bad or you’ve crisscrossed the harness connectors. They can go bad either at the same time or individually at some point in time. Factory Honda indicates the intake side is the “CMP” sensor and exhaust side is the “TDC” sensor. Normally, the ECU will throw a CEL if one or both of these sensors go bad. If only one is bad, you can actually swap them around to perform a trial & error test to confirm faultiness (CEL code will switch up). The actual sensors themselves are Hall-Effect type and are built the same. They work magnetically getting a reading from the cam pulse plates that are on the end of the camshafts. These sensor are not specific to which side of the head they’re used on, so that’s why you can swap them around and it will not hurt anything. Honda offers them in orientation styles – straight style or a 90 degree style. This doesn’t impact their performance, its just for plug orientation. Symptoms of a bad cam sensor(s) is difficult engine startup, can start up but runs terrible (stumbly) and can backfire, but should throw a CEL code!

Note: Rywire K-swap tuck engine harnesses have the CMP and TDC labeled reverse on purpose (TDC intake cam sensor / CMP exhaust cam sensor). He explains this on his K-swap engine harness product page. So if you run his harness and you’re having CMP and TDC cam position sensor codes its probably because you need to swap the connectors.

Mechanical Based Issues

- K20Z1 throttle body MAP sensor situation

This one is unique. If for whatever reason you’re using a K20Z1 stock throttle body with your Kswap, and you decide to switch to any another intake manifold, other than the K20Z1 PRB intake manifold, you will have a problem with the MAP sensor getting a lack of vacuum source/feed (basically choking the MAP sensor). It’s because of how Honda slightly changed up the design of the K20Z1 throttle body’s backside compared to a K20A2 throttle body. There’s no slotted vacuum channel on the backside of a Z1 tb like there is a on a K20A2 tb. That slotted channel pulls vacuum from the throttle body mouth and feeds the MAP sensor. The wonky Z1 tb design has a small hole for the MAP so its super easy to choke it up! The result of a choked MAP sensor is stumbley startups or starts up fine but once you get on the throttle the engine falls on its face anything above 3000rpm. There’s two fixes for this as shown in the photos below. (1-best option) cut a slit from the MAP hole to the bore of the tb or (2) using an aftermarket Z1 thermal throttle body gasket, cut a channel open from the MAP hole to the bore hole of the gasket. - Cam & crank timing is off and/or crank pulse plate is installed wrong

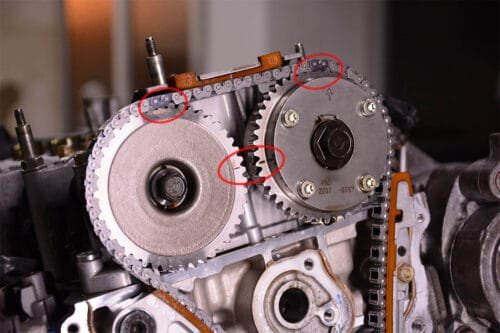

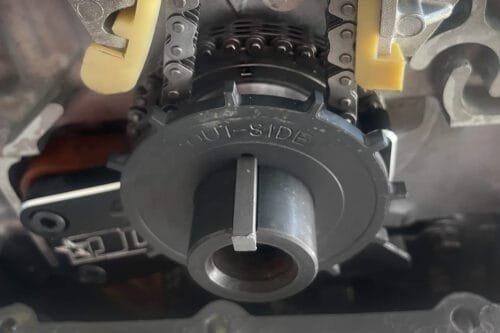

Check your cam and crank timing and see if TDC is off. Being off timing can totally affect startup and overall running behavior. If timing is really off a CEL code will be thrown. Another thing to double check is the crank pulse plate. It’s marked ‘OUTSIDE’ on one side for a reason. So if you replaced any timing components and reassembled and forgot about this plates’ orientation you might need to go back and check! Symptoms of a inverted pulse plate is no start up, engine will just spin, and it will throw a CEL code for a crank related issue.- White Mark = crank TDC.

- Crank TDC markers on the inside w/timing cover removed.

- Cam gear hash marks face to face at TDC. Chain alignment dots facing up. PS: don’t worry about the black chain links.

- Crank pulse plate in correct orientation.

- Fuel system setup is wrong (regulator, pressure, and/or line setup)

If you have your fuel line setup incorrectly to the fuel pressure regulator, such as the fuel feed going to the return part of the regulator – this can impact startup. If your fuel pressure is too low and isn’t set somewhere in the 45-55psi range, can also impact startup and overall running conditions. A faulty regulator can also impact startup, so make sure you get a worthy brand regulator! - Blown Fuse (ELD!)

Check your fuses – engine bay and under dash fuse boxes! Especially the ELD fuse. When this one blows out just about everything goes dead. - No fuel in gas tank

- Dead battery

Katman stole my children during the night